366 F&B User Manual

F&B User Manual-V.366

Food & Beverage User Manual

Version 366

Initial Release Date: Winter 2019

Contents

Manufacturer & Vendor Management

Creating & Editing Vendors/Manufacturers

Managing Vendors/Manufacturers

Setting Reorder Points and Pars from the Stores Tab

Performing On Hand Adjustments from the Stores Tab

Running Item History from the Stores Tab

Attaching Recipes to Inventory Items

Removing or Inactivating Items

Assigning COGS to Inventory Items

Disable automatic recalculation

Show only items with variances

With a Data Collector (YDIMobile)

Multiple Sessions for the same Physical Inventory

Emailing Purchase Orders to Vendors

EDI Receipts/Invoices and Return to Vendors

Maximum Short Description Length

Introduction

The Yellow Dog Inventory Food & Beverage User Manual contains all the essential information for you to make full use of our software. Yellow Dog Inventory is a feature-rich inventory management program designed to handle any type of F&B environment. Our software is very user friendly, and this manual will provide a detailed roadmap for everyday use, but should any problems or questions arise please contact us using the Support Information below.

Support Information

Support Hotline: 757.663.7514 (9am – 5pm EST Monday – Friday)

Emergency Support: 757. 663.7514, option 1

Submit Tickets to Support: Portal.Yellowdogsoftware.com

To access our Knowledge Base or Support Forum, click here.

A couple of basic things to keep in mind:

- All of your inventory management should be done in Yellow Dog Inventory. Items entered directly into your Point of Sale (POS) will not be recognized by Yellow Dog Inventory unless they are mapped as part of a one-way interface. Please contact your Yellow Dog Inventory implementation guide if you have questions about your interface type.

- Make sure the Yellow Dog Inventory client application has a connection to your database. Your implementation guide will work in concert with your IT personnel to ensure that the connection is in place.

- There is no limit to the number of Yellow Dog Inventory client programs you can have connected to your database.

- Required information is denoted by red text. Black text indicates optional information.

- Most objects have right-click functionality.

- Permissions vary for each user. If you can’t access something, check your employee setup under System Setup or have your system administrator check it.

- Filters for the data you see on the screen are at the top of the page. More on that later.

System Navigation

The Inventory Items screen, the first screen you see when you log in, is the main point from which most Yellow Dog Inventory functions originate. The left-hand side is our navigation menu, while the top section contains filters for the data displayed below.

There are two sections on the right-hand side. The first, to the far right, is the blue section called On Form Help. Each screen you encounter in Yellow Dog Inventory has its own little glossary and help section here. Hovering over the section of the screen in Yellow Dog Inventory will put a blue box around the correlating section of the on-form help, and vice versa. This can be a great help while learning the system, but if you’d rather keep your screen space for the program itself, use the right-pointing arrow on the top to minimize it to a narrow, vertical blue bar. If you need it again, just click on the bar.

To the left of that are our action buttons that assist with items, documents, etc.

Each section will be broken down in the pages to come.

Navigation Menu

The left-hand sidebar of almost all Yellow Dog Inventory screens is the navigation bar. Related groups of functions are divided into sections.

Item Management:

- Inventory Items: The primary list of all item data, able to be viewed, sorted and filtered in several ways. This is where most item creation and editing will be done.

- Matrices: Section to create several related but dimensionally-different items (e.g. small red shirt, small blue shirt, etc.) This is mostly used by retail clients.

- Recipes: This is where food and drink recipes are created and managed.

- POS Item Map: Items and Recipes can be linked directly to items created at the Point-of-Sale (POS) to deduct inventory for the sale of that POS item. This is also where COGS departments are attached to POS items.

- Item Lists: Create and maintain lists of items used for various functions (order guides, etc.) Any function in Yellow Dog that includes Add Items From… can pull in an item list.

- Label Queue: Print multiple labels for multiple items in one place here. When receiving using the Purchasing module, you can opt to add all received items to the Label Queue and print them later at your convenience. This can be used by F&B clients to create shelf tags.

- Schedule Retail Changes: Used for 2-way retail syncs only.

- Manual Sales Entry: Sales not pulled from a POS (for example, a food truck or catering event) can be entered here. These will show in sales reporting.

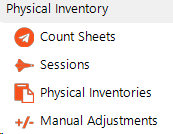

Physical Inventory

- Physical Inventories: Documents that will record the on-hand of items when they are counted. Counts can be entered manually or can be brought in from other sources.

- Count Sheets: A list of items that serves as a counting template. These can be organized in any order you like.

- Sessions: Lists of item counts taken using a mobile device running ydiMobile, a Yellow Dog counting app or manually entered.

- Manual Adjustments: This view displays changes made to an item’s on-hand outside of counting, POS sale, or purchasing; for example, waste, damage, and theft can all be recorded with a manual adjustment. Transfers between non-Yellow Dog managed locations can also be completed this way.

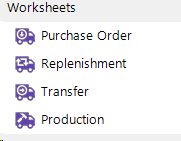

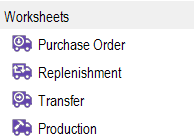

Worksheets

- Purchase Order: A single document that will then create multiple purchase orders for multiple stores.

- Replenishment: A flexible document that will generate multiple Purchasing documents to resupply outlets. Defaults to Transfers for moving stock from store to store, but can be set to any purchasing document.

- Transfer: A worksheet that can use multiple requests to transfer multiple items to multiple stores from a central location.

- Production: A tool that assists with assigning recipe creation to different production Groups based on requests from multiple stores.

Purchasing

- Requests: A document that indicates that items are needed. Can be converted into a Purchase Order or a Transfer.

- Purchase Order: Document of items that are required from a vendor. Can be converted into a Receipt or Invoice.

- PO Approvals: Requires a higher-level employee to confirm the accuracy/completeness of a Purchase Order. Can be set to use dollar total thresholds or a ranked hierarchical structure.

- Receipts: Acknowledges that items have arrived and will increase the on-hand of items on the document as of the time it is committed. Can be converted into an Invoice or a Transfer. EDI documents can be created as Receipts upon request.

- Invoices: Primarily used to track expenses on received orders. When used without Receipts, will add the quantities of items to a stores’ on hand as of the time it is committed. This is the final chance to affect cost of items with expenses. Invoices are the default document for EDI invoices.

- Transfers: Used to move items from store to store in multi-store locations.

- Return to Vendor: Tracks items that are being sent back to the supplier. EDI Credits will generate here.

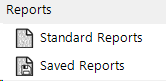

Reports

- Standard Reports: The list of all reports available in Yellow Dog. Most reports are filterable on time ranges, vendors, levels, etc.

- Saved Reports: Frequently generated reports can be re-run quickly and easily. Saves filters, sorting, etc. Use the date range dropdown (yesterday, last week, last 30 days, etc.) rather than specific dates. These Saved Reports can be automatically emailed out using the SendSavedReportsEmail application.

Common Setup

During implementation, your Guide will walk you thru the setup options, however you may find it necessary to make changes, add more details, or edit existing setup options. To do so, navigate to Common Setup.

Dimensions

Dimensions are most commonly used to specify information such as size and color. However, if you have other needs they can be used for anything you like, such as wine/beer varietals, regions, lead times on special order items, etc.

More Dimensions

The default Dimensions screen has two dimensions; however, eight additional dimensions are available if you need them. Please check your employee permissions if you do not have access to this.

Managing Dimensions

- To create a new dimension, click on the three dots next to the first empty dimension and enter a title for the new Dimension, e.g. Size, Color, Varietal, etc.

- Click “Create New…” and enter in the new Dimension. Click the “Save & Close” button if you’re done or “Add New” button to add multiple dimensions.

Removing Dimensions

- To remove a dimension, click on a dimension and hit “Remove”. If the Dimension is still assigned to an item, it will not allow you to remove it.

Inventory Levels

Levels are how inventory items are categorized in Yellow Dog Inventory and are used for reporting. Typically, the hierarchy is as follows:

Level 1 = Department

Level 2 = Sub-Department

Level 3 = Category

Level 4 = Sub-Category

So, the level scheme for an item might look something like this:

Department = Food Inventory

Category = Protein

Sub-Category = Beef

Sub-Sub-Category = Grass Fed

The amount of Levels created and used in the system is fully customizable. You may only require 1 level while another company would require all 4 levels in their tree structure. This is completely up to you and should be discussed and determined before the installation of Yellow Dog Inventory.

At any point, with the correct permissions, users can create, rename, remove, and perform any other edits to the Inventory Levels in the system.

Creating New Levels

- Open the Inventory Levels screen, choose either Add Department or select an existing department and click Add Category under…

- Enter a Code (numeric), description, and check the box(es) next to the store(s) that the level will be available in.

- Temporary levels are used by EDI syncs to create new items. Items in these levels need to be moved to their permanent levels weekly as part of new EDI item management.

- From the Interfaces tab, you can customize how Yellow Dog Inventory communicates with your POS system. Select which stores’ interfaces you’d like to see in this window to reduce the number displayed. This will especially help clients with large enterprises on a single database.

Please see the section on Interfaces for a brief overview of them and contact your support or implementation guide if you have specific questions.

Managing Levels

NOTE: There are many shortcuts throughout the system that will take you to the Levels Editor. Just look for the blue hyperlink.

Right click on any level from the Inventory Levels screen and this list of options will appear.

- Removing levels cannot be done unless there are no items assigned to that level. Otherwise, a popup notification will appear.

- Take care when merging levels. This cannot be undone except to recreate the merged level and move the items back manually.

- Levels can be moved by selecting the level you wish to move, right-clicking, then hitting Move and choosing where you want it to go.

Manufacturer & Vendor Management

Vendors and Manufacturers are created and managed in the same section in Yellow Dog Inventory. A vendor is required, while manufacturers are optional, unless your POS requires them.

Creating & Editing Vendors/Manufacturers

- Navigate to the Manufacturers and Vendors section and click Create New Vendor. You will be prompted to enter the Vendor Name. Click OK when complete.

- From the Details screen, you will see that a Vendor Code is automatically generated by the system. You can replace the generated code with your own if you prefer.

- From the Stores tab, you can choose which stores the Vendor will be available to. Check the box in the “Available” column of the appropriate store(s).

- You can also enter Accounting ID, Account Number, Tax Number, Terms and Customer Number as they are related to each store.

- The last section is the Contacts tab. From this screen you can enter in Vendor contact information including Email, Address, Phone Number and Fax number.

- You can also determine what stores the contact is valid for and if the address enter is used for both Order From and Return To. Entering in email addresses is particularly helpful if you plan on emailing purchase orders directly to vendors.

- To complete the Vendor creation process, click Save and Close in the bottom right corner.

Managing Vendors/Manufacturers

From the main Vendors and Manufacturers screen, you have the ability to view a variety of Vendor specific information such as: Active SKU’s, Inactive SKU’s, Total On Hand, Assigned as…, etc. You can also Create New, Edit, and Remove Vendors.

Primary Vendors

Yellow Dog now allows for Primary Vendors to be selected for items. To set this as a feature, navigate to System Setup. Under Global Options/Purchasing, select “Force Purchasing Documents to respect Primary Vendor”.

Then, under the item, on the Additional Vendors tab, set the Primary Vendor for the item. If a Request or PO is created for the non-Primary Vendor and the item is added, this popup notification is generated. Users will also see this notification if they attempt to convert a Request into a PO using a non-Primary vendor for this item.

Flags

Flags allow you to indicate storage locations, making ordering and physical inventories easier. To create a new Flag, click “Create New Flag”. Enter a Description, then click “Save and Close” if done, or “Add New” to add more. If you would like to change “Flags” to a more useful title, go to System Setup\Options\Labels.

Once you are done creating Flags, use the right-click option in Flags View in the Inventory Items screen to assign them to items.

Recipe Types

This page will allow you to create different recipe types for better organization within your recipes. For example, you could create “Appetizers”, “Entrees”, “Prep Recipes”, etc. Use the action buttons on the right-hand side to Create, Edit or Remove Recipe Types.

Production Groups

This section will allow you to create Production Groups to add another layer of organization to your recipes, specifically Production/Batch Recipes. Production Groups are meant to be used in conjunction with the new Production Worksheet module. By assigning groups, you can print worksheets to identify stations responsible for making requested Production/Batch recipes.

Events Calendar

The Events Calendar is a new feature in Yellow Dog that allows for the user to tag days with event types for filtering reports. You can also search past events using keywords in the Search bar.

Setting Up Events

- First, navigate to the Events tab under Common Setup.

- To set up Event Tags, click Edit Tags. Click Add, then enter in your first tag. You can either choose Save and Close or Add New to continue adding tags.

- The Tag is usually the type of category the event will fall under. For example, a stadium client may set the event tag to the league that is playing and/or to indicate whether it is a day or night game.

- To add a new Event, click the Create New Events button from the right hand menu.

- Then, add a description and set the dates the event will run through. Note: for a single day, choose the same start and end date and set the time for 12am – 11:59 PM, which is the default setting.

- Next, choose your Event Tag(s) for the Event.

Note: If you haven’t already created event tags, you can create them from this screen by clicking on the blue hyperlink next to the event tags field.

- Finally, add any Notes for your event, then save and close at the bottom right of the screen.

Events feature in reports

Once you have your events set up, you will be able to run sales reports using the events filters:

- Choose the Event Tag(s) you would like to run the report for;

- Set all other filters needed;

- Use the button to generate the report as usual.

Once the report has generated, you can now sort and group your reports by the Event Tags as well.

System Setup

This section of Yellow Dog controls the Admin related options of the system.

- Accounts: Used to set up Manual Adjustment reasons, Invoice expenses, COGS Departments & Categories, and accounting interface export codes.

- Autonumber: Algorithms used to auto-generate document codes and item SKUs.

- Interfaces: Where third-party codes for integrations are mapped. These can be set per Store, per Level, or per Item.

- Options

- Global: System behavior.

- Inventory: Item behavior.

- Fonts: System-wide font for item data and section labels

- Labels: Names of sections and titles can be edited here, e.g. Manufacturer can be changed to Supplier, Flag to Location.

- PO Approval Setup: Ranks for the PO Approval are created and maintained here. Every Location Type can have a different set of approval rankings.

- Print Templates: Used to define labels or any printable document.

- Employees

- Employees: List of user logins with employee access options, if not using groups.

- Employee Groups: A pre-defined set of store specific user accesses that can be quickly assigned to a new or existing user login.

- Employee Options: Allows for different login types, such as Active Directory or Windows.

- Employee Roles: Defines the hierarchical rankings for who is notified about POs for approval.

- Stores: List of outlets in Yellow Dog.

- Store Approval Types: Stores will have hierarchical PO Approval rankings determined by the store type. These are determined in the PO Approval Setup section.

Top Menu Bar

Log Out

This logs you out of Yellow Dog. We recommend doing this anytime you leave your workstation to ensure nothing is being done under your login without your permission.

Change Password

This requires you to know the old password. If you’ve forgotten your password and are unable to log in, please contact your system administrator or our Support department.

Password Recovery

Upon first login, users are encouraged to set up their password recovery.

- This can be done by navigating to the top menu bar and selecting “Password” recovery.

- Users will then be prompted to re-enter their login information.

- Next, users will be asked to choose and answer two security questions. These can either be selected by using the drop down or customized by personalized questions.

Note: Keep in mind, the answer cannot be in the question.

- If a password is forgotten, users can simply answer their security questions to reset and create a new password.

Refresh Data

This button forces the system to refresh the data that is being displayed. Occasionally, using this will clear up an issue you’re seeing with the data being displayed.

Recalculate Costs

This button will process any data up to that point and allow for the most up-to-date reporting. This will also refresh recipe costs. Larger databases with a lot of history will take more time to recalculate.

Help

- About – displays technical assembly information along with a link to our Knowledge Base. The Knowledge Base is a great place to review software documentation, videos, and other direct and indirect support resources to help assist you. This also includes live chat with a support technician during business hours 9am-5pm Eastern Standard Time (Holidays will effect these hours).

- What’s New – directs you to our “What’s New” page on our website, which provides the most up to date product and version release information.

- Upgrades –directs you to our “Upgrades” page on our website and allow you to book an upgrade with our team.

- Support Info – provides contact information for our Support and Sales departments. It also provides links to our Customer Portal and self-scheduler for additional training requests. All customers are allotted up to two free 2-hour training sessions per company per month.

- Announcements – periodically, Yellow Dog will distribute important and noteworthy information via our login announcements popup. This section of our Help drop down displays any previous announcements we’ve posted over the past three months, by date.

- Web Store – this will direct you to our Webstore where you can purchase additional labels or hardware.

Inventory Items Screen

You can change what data is shown on the inventory items screen by using the Views, Columns, and Filters on the top of the inventory items screen.

Views

There are fourteen different ways to view the inventory screen in Yellow Dog Inventory. Your views may vary based on your permission settings.

- Classic – This is the default setting. It will give you most of the basic information.

- All Stores – This shows all items for all stores in the database that the user has access to.

- Activity – This shows event dates for the items: Created First/Last, First Received, Last Received, First Sale, Last Sale and recent session.

- F&B Expiration – This view shows items with expiration dates set, how much is expired, and the oldest and newest expiration dates for each item.

- Flags – This shows basic information, plus the flag associated with the item.

- Recipe/Kit/Batch Items Only – This shows all kits, the recipes they are attached to, their ingredients, cost, and how they behave in the system.

- Third Party/Interface Codes – This view shows all pertinent interface information as of the last sync and is highly dependent on your POS set up.

- Merchandiser – This view allows for more specific item filtering based any or all up to 10 dimensions in Yellow Dog. This is mainly for retail users.

- Parent/Child – This view brings up all items with parent/child relationships, their SKUs, On Hand Counts, and usage.

- Problem Items – This view brings up all items with problems, including no cost or retail price, duplicate UPCs or missing Vendor information. Pay attention to items with no cost; these can significantly impact inventory valuation.

- Web Items - Lists all items set to push to and/or pull sales data from an interfaced web cart. There are additional right-click options in this view for setting web cart specific properties.

- Purchasing – This view shows On Hand, Size, Vendor ordering information, Par & Reorder Points and the Vendor Price for each item.

- SKU, Vendor SKU and UPCs – This view shows basic info, plus SKU, Vendor SKU & UPC. Mostly used by Retail clients or clients with barcode scanners.

- Interactive View – Item data fields, such as Long Description, Size, Color, Vendor SKU, Retail Price, Reorder Point, Par Level, etc., can be edited directly in this view, similar to how a spreadsheet behaves. Previous versions of Yellow Dog required a single Vendor to be selected, but now all Vendors can be displayed at once.

Filters

There are a few options for narrowing your search in the Inventory Items screen.

- Store – If you have access to multiple stores, you can choose the store that you want to view by selecting it from the dropdown box. This will show inventory and corresponding on hand quantities for items that are in the selected store, as well as any other information that can be specific to that store, such as retail price.

- Manufacturer or Vendor – Use the Manufacturer or Vendor dropdown to view only items that are assigned to the specified company.

- Levels – Use the Levels dropdown to view only items that belong to specified Departments and/or Categories.

- Other – By clicking on the “Other” dropdown you can choose to hide either parent items or child items from your view. Items without a Parent/Child relationship will remain in either view. Selecting the “No Count” option from this dropdown hides items for which you don’t track on hands.

- Include Inactive/Removed – If you check the “Include Inactive/Removed” button, all your removed and inactive items will be populated with your inventory items. Those items will be marked Removed or Inactive in their descriptions to help distinguish them from the active items.

- There is also a new column that shows Status: Active, Inactive, Deleted, or NoCount.

- Search – The search box functions as a standard search box. Type what you are looking for into the box, and Yellow Dog will immediately begin returning results. This feature also allows “or” searches to include multiple terms.

- Delay Data Fetch until a Search String is Entered – When this box is checked, no data will be displayed in the Inventory Items screen until the user types search criteria into the search box. This function is typically used in larger databases that may run slowly, to minimize wait times.

Blue Hyperlinks

These hyperlinks appear in any section where Vendors/Manufacturers or Levels can be selected from a menu.

Vendors and Manufacturers…

Clicking on this hyperlink will bring up a Vendors window. From here, you can view Vendors, Codes, Active & Inactive SKUs, Total On Hands, Total Requested and Total on Order. You can also Create New Vendors, Edit & Remove existing vendors and Merge them if you have access to do so.

Levels…

This hyperlink will bring up a Level screen. You can Add Departments & Categories, as well as Edit and Remove existing ones.

Choose Columns

You can customize what columns you see in each view by clicking “Choose Columns”. Each view has different column options depending on the information associated with the view. The default options for most of the views are: On Order, Reference, Current Retail, Vendor Price, On Hand, Dimensions, Description, Short Description, SKU, Vendor SKU, Vendor, and Manufacturer & Level. Additional columns depend on the view you are currently using.

Right-Hand Sidebar

These are the main action buttons for the Inventory Items Screen. These options are normally available in the right-click menu as well.

- Create new item starts from scratch in creating new items.

- Edit Item opens the item you have selected. You can also double click or hit Enter after selecting a single item.

- Remove item archives items with no on hand count. More information on removing or archiving items can be found later in the manual.

- Print labels prints labels for a single selected item. You can then choose the count and the template.

- Adjust on-hand quantity allows for a manual adjustment to on hand counts for items due to reasons not related to sales or purchasing actions.

- Create new item based on… copies certain attributes of the initial item, such as vendor, level, description, price and interface settings. It is a quick way to generate similar items.

- Item History Reports are great audit reports that show everything from changes to items to on hand adjustments from sales, receiving/invoicing and physical inventory on hand resets.

Right-Clicking

Right-clicking on an item on the Inventory Items screen brings up this menu of options, based on permissions.

- Create, Edit or Remove the selected item.

- Create Purchase Order containing the selected item or items.

- Set Level, Vendor or Stores availability.

- Set Dimensions such as Size, Color, Season, Material, etc.

- Set Evergreen Status: assign this status to items that do not age (i.e. aren’t dependent on season or don’t expire,) and that you may want to be able to filter out of some reports. This status is mainly used in Retail environments.

- Set Inactive or Active allows you to deactivate or activate items without opening the item itself. This means you can also perform this action on multiple items at once.

- Set Interface Code may or may not be available to you based on your permissions. This allows users to quickly change the interface settings of multiple items at once.

- Set Recipe Behavior is only available in the Recipe/Kit/Batch Items Only view. This allows you to quickly change recipe behavior for multiple items at once.

- Set Web Items Properties is only available in the Web Items view. This allows you to quickly change web item behavior for multiple items at once.

- Set Flags is only available in the Flags view. Use this to assign Flags to multiple items at once.

- Merge Items allows you to combine SKUs, UPCs, etc. of two or more items into one. This can cause issues with item behavior, so please contact your Implementation Guide or our Support department as there may be alternative methods to achieve what you are trying to accomplish.

- Parent Child Relationships:

- Set Parent/Child – allows you to create a parent/child relationship. Once you click this, you will be asked to select the parent item, then you will need to set the numerical relationship between the items in the Item Editor.

- Swap Parent/Child – changes the parent to a child item. This only happens if there is only one child per parent.

- Break Parent/Child – removes the relationship.

- Set as Recipe Ingredient so the item can be used to create Recipes.

- Trigger Items to Re-Sync to POS is important to note here: If you are having issues getting certain items to sync over to the POS, clicking this will manually add the item to the list of things the sync will push over the next time it runs.

- Print Labels allows you to print labels for the selected item. To print labels for multiple items, use the Label Queue.

- Adjust on Hand Quantity opens the manual adjustment editor.

- Create New Item Based On… copies vendor, level, description, price and cost of the highlighted item.

- Item History Report can be used to audit items. Choosing to show only on hands will display sales, receipts, returns, manual adjustments, etc. Choosing to show all information will also display changes to item cost, price, description, etc.

General Item Management

Creating Items

1. From the right-hand side of the Inventory Items screen, click Create New Item.

2. In the SKU Wizard pop-up, select the appropriate Level and Vendor for your new item. A SKU number will automatically be generated for you based on the Autonumber sequence set up during implementation.

In the example, only the Department code (030) is part of the SKU that is being generated for the new item.

Copying Items

Yellow Dog Inventory makes it easy to quickly create or copy item data to a new item with a unique SKU number.

- Highlight the item you want to copy and click “Create Item Based on [Item]”.

- Click “Yes Copy” to open the populated SKU wizard. Levels and Vendor can be changed here.

- Click OK to open a new Item Editor screen for the newly created item. Notice that all the data from the original item has been populated in the new item but with a new SKU. Make your changes and click Save and Close.

Item Editor Tabs

F&B Details Tab

In most instances, you will use this tab to build new and edit existing items.

- The SKU, Level and Vendor have been auto-filled based on your selection in the SKU Wizard.

- Enter in Description, Store Assignment and Size. Note: The Size you fill in here should be your primary counting size.

- “How is this item ordered or received?” – here you will fill out any purchasing information. In the example above, the item is only available by the case. If the case can be split, use Purchasing Item 2 (new size) to create the split. If you plan to use EDI for this vendor, the Vendor SKU must be filled out for it to work properly.

- “How is this item used in recipes?” – use this space to fill out information on recipe ingredient items. In this example, a case has 60 each in it.

- In the example below, instead of a count, the ingredient item has a volume. Entering in a cup measure will allow you to convert the item to any volume unit of measure, i.e. teaspoon, liter, etc., while filling out a weight will allow you to use any weight (ounce, gram, etc.).

- Yellow Dog is capable of handling yield calculations on items such as house prepared custom protein cuts. Simply enter the usable percentage into the field labeled “Usage” and the system will automatically determine how much to deduct from on hand when this item depletes, and then distribute cost appropriately. This can be applied to more than one cut for a single pre-production item. For example, the same side of beef could be used for steaks that are at an 80% yield, while also being used for ground beef at a 94% yield.

Stores Tab

From the Stores tab, you can set Reorder Point, Par Level, Bin Location, Tariff Code and Flags. Make sure the item is available in the appropriate stores by selecting them in the Available column.

Multiple Price Levels

This is used in Retail or two way integrations to allow for retail prices to change during specific timeframes set up in the POS.

Setting Reorder Points and Pars from the Stores Tab

Reorder points and pars work together to give you a simplified, automated way to create a purchase order, based on item on hand. Reorder points will tell the system at what point to trigger the item to be purchased, while Pars will tell Yellow Dog how many of your item needs to be ordered to get back to the desired inventory level. To set those points, simply enter the numbers in the associated fields.

Performing On Hand Adjustments from the Stores Tab

On hand adjustments are usually intended to track damage or waste, or to reset on hand quantity due to a counting error. To make an on-hand adjustment from the Stores tab, you will click the button labeled “Adjust On hand for [Store]”. You must enter a Reference, and Accounting Code if applicable, to make the adjustment.

Running Item History from the Stores Tab

You can also generate a store specific item history report for the item you are editing.

- Highlight the store you’d like to run the report for,

- Select “Item History Report for Store_____”,

- Choose to see all adjustments or only on hand adjustments and hit “Ok”,

- Choose to Export, Save, Print or Close the report when finished. Remember you can re-sort the report or choose additional column by selecting “Change Columns, Sorting and Grouping” hyperlink.

Add Child Item Tab

Parent/Child relationships are most commonly used for inventory items that are need additional sizes to count in a physical, purchase or use in a recipe. Using the F&B tab to create Purchasing and POS items will create child items automatically.

Other Details Tab

Use the checkboxes to specify how you’d like an item to behave. This can include:

- Making it inactive – takes the item off the active item list, but the on hand remains; useful for discontinuing seasonal items and product brought in for special events.

- Setting it to no count – useful for items such as cleaning supplies or vendor-supplied displays that you don’t necessarily want to inventory.

- Making it a recipe ingredient – this must be checked for an item to be added to a recipe. This will be checked automatically if you use the F&B Tab to make the item an Ingredient Item.

- Whether the item can be added to or affected by manual adjustments or physical inventories.

- Setting the item to be sold at a point of sale or used in purchasing documents.

- Telling Yellow Dog Inventory to prompt users to print labels for the item when it’s received.

- Blocking the item from being used in Transfers – particularly useful if you only want to transfer a specific size between stores. This will allow you to block sizes that should only be used for recipes or counting, not transfers.

- Evergreen – this allows for items with no “aging” that are excluded from those reports. Mainly used by Retail sites.

Note: These behaviors may be affected by whether or not the item has a recipe attached, and that recipe’s behavior. For more info, see the “Create Kit or Recipe Tab” section.

F&B Other Tab

This tab can be used to set Volume and Weight instead of the F&B Details tab. You can also set Tare Weight for items sold using scales. Tare Weight is stored for your information only and does not affect how anything is calculated or reported.

Expiration days are useful for:

- batch recipes created that are good for a certain period of time (e.g. soups and sauces for 7 days),

- product from vendors that have a consistent expiration date, and

- product where there is an agreement with the Vendor that they will pull product after a certain time of it being on your shelves, i.e. dairy products, periodicals, etc. Because the expiration of most products is rather fluid, this should be used as a guideline and not a drop-dead date for anything. For example, in a regular vendor relationship, the milk you order today might be dated for 24 days from when it arrives. However, the milk you receive next week may only have a date of 18 days.

Create Kit or Recipe Tab

This tab is used to assign recipes to inventory items such as prepared product that needs to be counted during a physical inventory. Mainly, this tab is used for assigning Batch or Production recipes to items, however we will go over the additional recipe behaviors available. .

Attaching Recipes to Inventory Items

To connect a recipe to the item, click the ellipsis (…) next to “Kit/Recipe”. This will bring up the “Lookup” screen where you will need to select the appropriate recipe.

Recipe Behavior

The Kits/Recipes tab makes assigning behaviors to your kit/recipe items simple with a dropdown menu of recipe item behaviors:

- A Batch Recipe item is made ahead of time but not produced in Yellow Dog using manual adjustments. When added to physical inventories, Batch Recipe Items will bring in their ingredient items, along with any related batch recipes and their ingredient items. Any counts to Batch Recipe items will adjust the ingredients’ on hands. This is the most common recipe type used.

- The POS Menu Item Recipe is not used in most implementations. This behavior was created for 2-way integrations. These recipe items aren’t produced until they are ordered. A burger might have a recipe that includes the bun, patty, and toppings. While the ingredient items are counted separately, they are sold as one unit.

- Production items, made in house to sell, are produced in Yellow Dog through manual adjustments, which is the only time their ingredient items are affected. These items have an on hand and can be counted in physical inventories, but they do not bring their ingredient items in to physical inventories with them.

- The Production Transfer Item behavior allows for a two-step process where one location produces a recipe item and another sells the recipe item as is. The “Production Store” will have ingredients subtract from inventory upon a Transfer. During the transfer, the Store To will receive an on-hand value tied to the recipe item for their use in selling. No ingredients will deduct from the Store To’s inventory when the recipe item is sold; the on hand value of the recipe item will simply decrease.

- The Retail Kit behavior allows users to assemble and disassemble the kit, count the kit in physical inventories, and sell or return the kit at a POS. The ingredient items are only affected by manual adjustments. These kits are usually store-assembled gift baskets or bundles of items. This behavior is very rarely used in F&B environments.

- The Purchasing Kit behavior allows users to receive by the recipe and sell by the ingredient. While more frequently used in retail operations, a good example of this would be a mixer assortment purchased together. One “recipe” might consist of the “ingredient items”: 6 bottles of strawberry daiquiri mix and 6 bottles of pina colada mix. These recipes only work if the item count is consistent for each order.

- The final behavior is “Other”. This behavior is used to set non-standard, possibly conflicting, item behaviors and is often very rarely used.

If you have questions about kit behaviors, please contact your implementation guide or Support.

Additional Vendors Tab

This tab allows you to manage additional purchasing options.

In this tab you can:

- set additional vendors and prices for items,

- set additional Vendor SKUS from the same vendor (especially helpful for those clients with EDIs. The Create Alias option in Invoices uses this feature. For more information, see the EDI subsection of Purchasing.),

- view or clear the vendor price history for the item you are in,

- mark a vendor as Primary (which will block users from ordering from other vendors if “Respect Primary Vendor” is enabled in Global Options).

Item Reports Tab

This tab allows transaction level reporting filtered down to the item you are currently editing for faster analysis.

Purchasing Activity Tab

This tab displays all purchasing activity related to the current item and provides the ability to open the source document.

Pictures Tab

Using Amazon S3, the pictures tab allows you to associate images with your inventory items. High resolution images are saved to S3 while thumbnails are available for viewing in the Yellow Dog client.

Interfaces Tab

This tab will depend greatly on the POS and interfaces set up for your store. Please contact Support or your implementation guide if you have questions.

The rest of the tabs in the Item Editor are geared towards Retail operations. A brief explanation of them follows, but speak to your implementation guide if you would like further information or access to these tabs.

Retail Schedules Tab

This tab is useful for viewing retail cost history/clearance/sales/etc. on specific items. A sale can be configured using the Schedule Retail Changes menu on the main YDI screen.

Additional UPCs Tab

This is another location for managing item UPCs. The UPC Check field will notify you of the type of UPC used, or if it is an unrecognized barcode type.

If you have more than one UPC for an item, enter them here.

Label Queue Tab

This tab allows you to add the item to your label queue.

Web Properties Tab

The Web properties tab is used to add item details for a 2-way web store interface.

Removing or Inactivating Items

Removed Items are items that you don’t plan on reselling or reordering. These should be removed from the system when the on hand reaches 0.

- To remove an item, highlight the item and click Remove Item.

- Make sure the On-Hand Count is zero before you attempt to remove an item from inventory.

- Use Adjust On Hand quantity if you need to manually deplete the remaining inventory.

- If there is an On-Hand count for the item, you will receive a popup notification:

- To un-remove an item, double-click on the item and click Yes Undelete. The item editor screen will open for the item. Click Save and Close to complete the undelete process.

Inactive Items are typically seasonal product that you plan to store until the next time you want to sell them. These items usually do not expire and do not require the stock to be 0 to be removed from your everyday inventory item view(s).

- To set an item to Inactive, navigate to its Other Details tab in the Item Editor and uncheck the “This Item is Active” checkbox.

- Depending on User Permissions, you can also achieve this by right-clicking the item on the main inventory items view and selecting “Set Inactive”.

- To set an item back to Active when you are ready to sell it again, use the right-click “Set Active” option, or re-check the “This Item is Active” checkbox in the Other Details tab for the item.

Once an item has been removed or set to inactive, you can view it by checking the box in the Inventory Items screen that says “Include Inactive/Removed”. The items will be flagged with (removed) or (inactive).

Manual Adjustments

To remove item quantities from inventory (waste, sampling, breakage, known theft, etc.) or to affect the on hand of a production item and its ingredient items, you will be using Manual Adjustments.

- In the Inventory Items screen, find the item(s) you plan on adjusting. Highlight the item(s) and hit “Adjust on Hand Quantity” on the right-hand side of the screen.

- Yellow Dog will prompt you to select the store in which you will make your adjustment; Manual Adjustments are store-specific.

- You can change the date/time or keep the current pre-populated information. This allows you to set the date and time the adjustment will affect the item’s on hand.

- You can adjust multiple items at once.

- Choose “Add Items” and select the other items you wish to adjust.

- Or choose “Add Items From…” and chose your source.

- If you are adding items manually, you will need to enter in quantities.

- Fill in the Reference field. You will not be able to submit an adjustment without a reference.

- If your company requires it, you will need to select an Accounting code from the dropdown. Please see the next section for information on setting Accounting Codes.

- Once you are done, click Submit.

- Hitting “Esc” or “Cancel” during the adjustment will exit out without saving your changes. Finish your adjustment in one go.

Accounting Codes

Accounting Codes allow the user to set standardized codes for things such as waste; production of recipes; transfers to departments not in Yellow Dog, such as HR; etc.

To create Accounting Codes for Manual Adjustments,

- Navigate to System Setup\Accounts\Manual Adjustment Accounts tab.

- Choose “Create New Accounting Code” and fill out a description.

- If you have different Accounting codes for Stores you can use the checkbox to mark codes inactive at certain stores in Yellow Dog. This will prohibit that code being used in any manual adjustments for the selected stores.

- If you are going to set up an accounting integration, fill out the gold/tan Manual Inventory Adjustment column with the appropriate GL codes.

- Lastly, decide whether you would like the accounting code to affect COGS. For more information on COGS, please see that section.

Manual Adjustments List

We’ve created a new screen that will allow you to view all the manual adjustments in the system. This list can be filtered by date, level, vendor, and store, as well as sorted by column like the main Inventory Items screen. You can also choose to include Auto-Zero adjustments in this view which will show each adjustment done by maintenance to zero the on hand of an item marked as Auto-Zero.

Recipes

A Recipe is a group of items that are combined to be sold as a single item in the Point of Sale. While there is only one kind of recipe you can create, the same recipe can behave differently when attached to different inventory items and assigned different behaviors, e.g. the recipe for a club sandwich used in the restaurant and produced when ordered can also be used as a Production recipe for a grab-n-go option. For more information on Recipe behavior, see the section on the Create Kit/Recipe tab.

You can create different Types of Recipes (e.g. Apps, Grab-n-Go, Batch, Buffet, etc.) by selecting Recipe Types under Common Setup. This can be useful in organizing your Recipes.

- To create a new recipe, navigate to Recipes and click Create New Recipe.

- Give your new recipe a description, use the dropdown menu to select the appropriate recipe type.

- You can also choose to set a Production Group (see Production Groups under Common Setup for more Information) or make the recipe Inactive.

- Click “Add Ingredient Items” and from the Item Lookup screen, you can sort through and search for items in the same ways that are available on the Inventory Items screen. Once you have selected one or more items, click select and those items will be populated on the Recipe Editor screen.

*PLEASE NOTE: only items marked as useable in Recipes will be displayed. You can check whether an item can be used in Recipes by opening the Item Editor and navigating to the Other Details tab.*

- You can also add recipes to another recipe. We often refer to this as “nested recipes”. For example, you can have a recipe for béchamel inside a recipe for macaroni and cheese. Click “add Ingredient Recipe” to do this. This works best if the ingredient recipe has a yield assigned to it.

- On the Recipe Editor screen, you can change the quantities of the Ingredients in the Recipe. Always change the unit of measure (UOM) before the quantity. Your Extended Calculated Cost (the total cost of that Ingredient per Recipe) is generated automatically. You may also add notes to each Ingredient if you wish.

- Additionally, two calculations are available at the bottom of the Editor that can help manage your recipe pricing. The first allows you to set a Target Cost Percentage to derive a suggest retail. By default, the cost percentage keeps the same percentage across all recipes. The second option allows you to input your current or Desired Retail to derive the current cost percentage.

- You can also set the Target Cost Percents independently for each recipe. Navigate to the System Setup section within Yellow Dog. Then click on Options > Global at the bottom of the page under Recipes is a check box that says, “Allow Recipes to have individual Target Cost Percents.” Check this box and choose a default cost percentage. You will now have the ability to change this cost percentage for each recipe in Yellow Dog.

- The Yield / Used By tab, allows you to fill in any Yields for the recipe you are working on. You can define the recipes yield by volume, weight or portion (this is particularly important when creating batch recipes that will be nested in Menu Recipes). This screen also allows you to link Recipes directly to POS items and when the POS item is sold, all of the recipe’s ingredients will deduct from inventory.

- To attach the recipe to its POS item. click on the “Linked to POS Items” space and check all POS items you wish to attach the recipe to.

- The Instructions Tab allows you to enter the steps for making the recipe. This can be used to create Recipe Cards.

- The Pictures tab allows you to attach photos directly to the recipe. High resolution images are saved to S3, while thumbnails are available for viewing in the Yellow Dog client. Pictures can be uploaded or captured on your mobile device using a YD App.

- The Links tab allows you to attach a URL to a recipe. This is helpful for any videos you may have that demonstrate how to prepare the recipe. Links will automatically open in your web browser.

POS Item Map

POS Item Mapping allows users to attach recipes to POS items in one-way interfaces and map COGS categories. As with the level interfaces, you can now be store-specific when setting these.

To begin, choose the store that you’re working with. If your stores share a POS server with identical item numbers for items, then select all the applicable stores. If your stores are on separate, or non-identical servers, choose one store at a time or uncheck “Automatically select matching rows”.

Once you start mapping POS Items or COGS departments, click “Hide POS Items that have…” to shorten the list of items you’re working with.

To map a POS item to a recipe:

- Click “Show recipe columns”, then use the ellipses to select a recipe.

- Or, if the item only has one ingredient item, or you would prefer not to build recipes through the recipe module, check “show ingredient columns”. Make sure you confirm the count on the UOM.

Other options:

- Search – behaves like the main Inventory Items Search.

- Ignore POS Item – removes the POS item from view. Check “Show ignored POS Items” to bring them back.

- Don’t Ignore POS Items – brings back an item you’ve ignored.

- Copy Recipe – allows you to assign one recipe to multiple items – helpful when working with multiple revenue centers or multiple items with the same recipe.

- Paste Recipe – the other half of the Copy Recipe function.

- Insert unsold POS item – Items that have been sold since the sync have been run are automatically added to the list. This allows you to add POS items that have no been sold yet. This is NOT RECOMMENDED.

- Set COGS Account/Reset COGS Account – this will be covered in the main COGS section below.

COGS

This feature provides Cost of Goods Sold (COGS) reporting but doesn’t require the use of recipes. We have added new COGS accounts which you can have automatically assigned to new inventory items via level interfaces as well as manually assigned by item. The COGS account can then be associated to the revenue generated by the POS menu items.

For information on manual adjustments and COGS, please visit the Manual Adjustment section of the manual.

To begin this process, you’ll need access to the Accounting/Other section under Interfaces. If you do not have this, please contact your Implementation Guide or Support.

Creating COGS Accounts

- Navigate to System Setup, then Accounts, and select the COGS accounts tab.

- We have set up default COGS accounts for you to use or customize to your property’s needs.

- To create, edit, remove or rearrange COGS accounts, use the buttons on the far right of the account list.

- You’ll need to provide a Department at minimum for your account. You can also create a Category.

Note: Inventory Items can use the specific Department: Category accounts and report on both, while POS revenue can only use the Departments.

Assigning COGS to Inventory Items

You can assign COGS to inventory items by Store, Level or Item, just as you would any other interface. And just like other interfaces, items assigned to Levels where COGS is set will inherit the level’s setting. To narrow down the interfaces shown in the tab, use the Filter to only show COGS.

You can also set them from the main Inventory Items screen. Highlight the items you wish to set to a particular account, then right click and choose “Set Interface Code”, then “COGS”.

Assigning COGS to POS Items

To assign COGS Departments to POS Items, use POS Item Map. Navigate there and select the stores you wish to work on. For more information on how to navigate POS Item Map, go to the section on it. You may need to scroll over or adjust the columns to see COGS Department.

There are two ways to set COGS here, by single item or multiple items at once.

- To set item by item, select the ellipsis next to the item you wish to set COGS for. It will bring up a list of accounts; click on the one you want and hit Select.

- Alternatively, use the Ctrl+Click or Shift+Click function to highlight the items you wish to set to the same account and, from the lower right-hand button on the screen, click “Set COGS for … POS Items”, or right click on the highlighted item(s) and select “Set COGS…”.

- To remove the COGS for an item, click the red X or the “Reset COGS Account” button.

Reporting on Cost of Goods

We have created several COGS-specific reports that will allow you to view the data that has been generated around your cost of goods departments and categories. These reports will require the user to select a starting and ending physical inventory, and all report data will be centered between those two physical inventories. For more information on COGS reporting, please see our Reports manual.

Item Lists

You can also create and save items into Item Lists. These are handy to create if there are items that are frequently ordered together, you need to keep a barcode/SKU sheet by the register for items without barcodes, you want to create order guides, or to keep your physical inventory process organized.

Item Lists can also hold Quantities per item. We’ve added a Quantity column on the main page to quickly identify those lists that have quantities attached.

Click “Create New Item List”, add items from the Item Lookup, and reorder and remove them as necessary. You can also add items based on Par Levels; Sales, Transfers & Adjustments; Sales; GoFetch; ydiMobile; an Excel or CSV file; or another Item List.

Manual Sales Entry

Manual Sales Entry allows you to create simple, basic sales transactions using your inventory items without going to your POS. This can be useful for off site sales, like a food truck in the example below.

- Choose the Store you wish to adjust the items from.

- Click on the arrow of the next blank line; this will make all fields editable in that line.

- Search for items to adjust by clicking on the SKU ellipses.

- You can also change information such as Transaction Date, Retail, Discount, Reference and Ticket by selecting those fields.

- Enter in the quantities to adjust by using the + or – buttons or by manually entering in a number.

- Once you’ve reviewed the sale, click on the Green Arrow to commit the line your working on or you can use the button on the bottom right corner to “Commit All Open” sales.

Sessions

This screen allows you to manage sessions from mobile apps, handheld devices, or those created directly in the client. They can be filtered down to a specific store’s sessions, session status or to those sessions containing a specific item.

On this screen, you can:

- Create New Sessions – allows you to create a new session directly in Yellow Dog for manual data entry of a count sheet.

- View Session – allows you to view any review any existing session. Keep in mind that if you are using a Mobile App a session is not completed until the status is “Finalized”.

- Delete sessions – useful for keeping session lists organized. Once this is done, there is no way to undelete a session.

- Import 3rd Party Session – Allows the import of Third Party Sessions that have been added via our API.

- Mark as Processed – Use this to indicate that a session has been used in a physical or another document and should not be used again.

- Adjust on Hand- allows you to use a session to make a bulk manual adjustment. Whatever session you have highlighted when you hit “Adjust on Hand” will then load into a Manual Adjustment editor. Users will still be required to enter Accounting and Reference fields based on system setup.

- Force Recount – If using one of the Mobile Apps, force recount will send the session back to its original device to be recounted.

- Create Physical – this will allow you to highlight one or more sessions and create a physical inventory based on only the items that are in the session. This is not our recommended option and should only be used with caution as the likelihood of leaving off items that should be counted is high.

- Launch Sync YDI with Handheld– shortcut to launch the handheld sync. Works the same as the desktop shortcut.

- Configure Sync YDI with Handheld – This is a shortcut to configure the handheld sync. Your implementation guide will walk you through configuring the sync. This will need to be done on each computer the handheld is plugged into.

Physical Inventories

Yellow Dog Inventory gives you the ability to periodically check actual on-hand counts against the counts as reported by Yellow Dog Inventory, and then update Yellow Dog Inventory with new on-hands. This process is called a Physical Inventory.

Creating a Physical Inventory

- Navigate to Physical Inventories.

- Create a new physical inventory by clicking the Create New Physical Inventory button on the right side of the screen. If you have access to more than one store, you will be prompted to select the store to perform the Physical Inventory for.

- Select the items you want to count. You can select “Add active items for store …, filtered by vendor or level (recommended)” or you can Select from other options. It is *highly* recommended that you choose the first option.

- If you would like to count specific Vendors/Level combinations, you can make that selection here.

- If you are confident that any items that do not have an on-hand count in the system will not need to be counted, you can remove them by selecting “Skip Items with zero on hand”.

- From the Review screen, you may add, edit, or remove items that should or should not be part of this Physical Inventory. Once all changes have been made, click “Select All ### Items”

- Now, bring in your counts if you have already gathered them. You can add from a GoFetch session, a regular Session or an Excel, CSV or text file. Alternatively, you can hit Skip to enter manually. You can find information on the ways to count inventory under “Inventory Count Options”.

- Each count source you choose will create a new column in the editor.

Physical Inventory Editor

Effective Date/Time

From the Physical Inventory Editor screen, you can set the Effective Date and Time that this Physical Inventory will be applied to the system.

IMPORTANT: When committing a Physical Inventory, the counts will be applied to the system as of the EFFECTIVE DATE AND TIME that YOU set. This gives you the ability to count on a Sunday evening and come back Monday morning and commit the counts without losing any data integrity. THIS DOES NOT MEAN that you can take a week to conduct your Physical Inventory and expect the inventory counts to be accurate. In general, it is best to complete your Physical Inventory at one time.

Columns

Each source will bring in a column, however, you can create new ones with the buttons on the right hand side:

- Add Column

- Rename Column

- Remove Column

You can use the “Choose Columns” option to hide these at any point.

Sort By

From your new Physical Inventory, use the “Sort By” dropdown to decide how your worksheets should look. The sort order on the screen will be how your worksheets will print.

You can sort by:

- Item

- SKU

- Item List/Count Sheet Order

- Item List/Count Sheet Order (Reverse)

- Level, Item

- Vendor, Item

- Manufacturer, Item

- Dimension, Item

- Bin, Item

- Variance Quantity, Item

- Variance Quantity (Descending), Item

- Variance Cost, Item

- Variance Cost (Descending), Item

“Print Worksheet” will print based on the sort order chosen.

Find

Search keywords in the description, or search for a specific SKU.

Check “Hide rows that don’t match Find” to only show filtered items.

Disable automatic recalculation

If recalculation takes longer than 2 seconds, this will appear as an option. Check to speed up the physical and reduce auto processing.

Show only items with variances

If checked, the editor will refresh to only show items that have a variance to assist with validating counts.

Hide All Flag Columns

If using flags, once you’ve entered your counts, check this box to refresh the editor to remove those columns for easier analysis of your inventory.

Finishing an Inventory

Once you have updated all the inventory counts, you can see information on the physical inventory at the bottom of the screen. The variance count indicates the number of items that have counts different from what the Yellow Dog system has calculated should be on hand. A positive number means you have more inventory, a negative number indicates less inventory on hand than calculated. The variance cost is calculated using the cost calculation you have chosen; Yellow Dog’s default is weighted average.

We recommend running the Detailed (Select by Physical Inventory) report under Standard Reports/Physical Inventories before committing. You will need to select Show Uncommitted.

When all counts have been entered and you are ready to commit the Physical Inventory, click Commit Physical Inventory.

You have the option to either Commit Physical or Commit Physical and Recalculate costs. If you have many inventories to review and commit, we recommend skipping recalculating and running Maintenance afterwards. Otherwise, you can commit the physical and recalculate to finalize.

If you have items that have not been counted, the system will prompt you. If you are confident any items that were not counted do not need to be counted, click ‘Yes Commit Counts”. This will set any items that were added to the original inventory but not counted, even those with counts in the system, to zero.

If you did not miss items, the system will simply prompt you to commit the inventory. Both prompts will also display the effective date and time.

Run the Detailed Report again as a final check. Most clients use this report to turn in their numbers to the accounting/finance department.

IMPORTANT: Once you commit the physical inventory, the counts that you entered in to the “Counted” column will now become you current on-hand number. If a count is left blank, it will result in updating 0 on hand for the item.

Inventory Count Options

With Flags

You can use Flags to print worksheets. Flags are custom markers in Yellow Dog Inventory to denote a storage location. For example, shelf stable juice may be under the “Dry Storage” flag as well as the “Walk-in Cooler” flag.

- Choose a Flag from the dropdown, then choose “Print Worksheet”. If you wish, you can also apply a sort order using the Sort By filter. You will need to follow these steps for all Flags you wish to print count sheets for.

- Save and Close and perform your manual count.

- Choose the Flag you are entering from the dropdown and enter your on hands in the column for that Flag. You will notice items shared between Flags will have multiple places to enter in counts. These will add together to create a final on hand number.

- If using flags, you also have the ability to Hide All Flags Columns by checking the corresponding box which will allow for easy analyzing of your physical.

With Count Sheets

- To set up a count sheet you will navigate to the “Count Sheet” tab in the physical inventory module. From here you will be able to create new sheets as well as edit existing sheets.

- To create a new sheet, you will click the Create New Count Sheet button on the right-hand menu. Count Sheets are store specific so if the user creating has access to more than one store, they will be prompted to choose which store this Count Sheet will be used for.

- Once you’ve selected your store, enter in a description in the Count Sheet editor and then decide how to bring in items:

- Add Item- simply grab any item available.

- Add Items From- here you can choose from several methods such as pars, sales, text CSV or excel files.

- From Flags- whenever you add a flag to a count sheet, it will add any items currently assigned to that flag as well as add any additional items added to that flag in the future.

- Level- this will add all items under the chosen level and add any additional items assigned to that level in the future.

- Additionally, we’ve added a few drop down choices you can use in lieu of selecting individual items:

- Include ALL items in the store – this will bring in every item into your count sheet. This is not the recommended option as your Count Sheet will typically be very long and hard to organize.

- Include all items in the store that do NOT belong to a flag – This is useful as a catch all if using flags. This count sheet will make sure any item you haven’t assigned to a flag will appear in a list to ensure nothing is missed in counting.

- Include all items in the store that are NOT on any other count sheet – Similar to the option above, this option will ensure any items you have not assigned to another count sheet will be grouped here to make sure no items are missed in counting.

- Once you have chosen your method of adding the items to your count sheet, set them in the order needed by highlighting the item and using the arrows to the right to order the items as needed.

- Once the sheet is set up as needed, use the save and close button at the bottom right.

At this point, you can either print your count sheet or upload it to the new mobile platform on your smartphone or connected device.

Please see the mobile app manual for further information on this.

If you’re using printed sheets, when your count is complete, you have two options to enter in your counts.

- Return to the Sessions screen and create a session for each count sheet. This is helpful because multiple people can key in sessions at the same time without affecting the inventory and all your items will match up in the exact order of each count sheet. You would then bring all the sessions into your physical when prompted.

- Key the counts into the physical editor. You can do this by using the “Add Column” button to create a new column to add counts into or updating and adding to the On Hand counted column. Depending on the sort of your count sheets, this method may not line up exactly and require a longer data entry time.

With a Data Collector (YDIMobile)

Follow the steps in the beginning of this section to create a new physical inventory.

Make sure the device is connected to your PC via either the cradle or USB cable and the scanner is powered on. To test if the handheld is truly connected, open Windows Explorer and ensure that YDIMOBILE has become an accessible drive.

If this is your first time using SyncYDIwithHandHeld.exe, please refer to the ydMobile guide.

You can configure the handheld to sync for a single store, which is useful when there are multiple stores to be counted. Simply go to the “Stores” tab on the sync, select the store you wish to count and hit Go on the main tab. This will limit the sessions stored on the handheld to the store you have chosen, reducing the number of sessions you need to go through to import your counts.

- Run SyncYdiWithHandheld.exe (this will update the device with all new items and updates). The sync can generally be found either as a shortcut on your desktop or in C:\ YellowDogInventory\ SyncYdiWithHandheld.

- Disconnect the device from the computer and follow the onscreen instructions to launch YDIMobile.

- Once the program opens, select your employee. Note: Depending on the version you are using, it may not prompt for an employee. In that case, skip this step.

- Click Count Inventory Items.

- From the Select Session screen, click Create New Session and enter a session name. Choose something that is both unique for this inventory and for the handheld if there are multiple handhelds being used. It can be helpful to name sessions based on date, store, and employee name. For example, Bethany, Mary, and Curt are each using a scanner to count both the Lobby Gift Shop and the Casino Store on January 17th. Recommended session names would be:

- Jan17Casino Bethany

- Jan17Lobby Bethany

- Jan17Casino Mary

- Jan17Lobby Mary

- Jan17Casino Curt

- Jan17Lobby Curt

- Then, select the store you are counting if you have access to multiple stores.

- Click “Add Item”.

You are now ready to scan your items. Use the bright blue buttons on the sides of the device to enable scanning.

When an item is scanned you will be prompted to enter a count for the item. Yellow Dog Inventory can handle decimals if necessary. Use either the on-screen numbers, +/-, or the keypad located at the bottom of your handheld to enter in your counts. Once completed click Submit and move on to the next item. Alternatively, scan each barcode and the system will tally the counts for you.

Occasionally, an item with an unrecognized UPC will be scanned. From here, you can either

- Search for the item using the search field below the error message. Click the item you want associated with the barcode, and enter your count. Or,

- Click “Create Item” and enter in the description. Fill in any identifying information that will be helpful as you will be able to finish creating the item when you import your counts.

If you make a mistake adding a UPC to an existing item, hit File, then Edit (Item), click in the UPC field, then follow the directions on-screen. Click the UPC you wish to remove, then hit Yes when prompted. Click Close, then Close again. Change the count to 0, then hit Submit. Then, hit “Add Item” to go back to scanning.

- Once your count is complete, click Close and then Exit.

- Open your Physical Inventory in Yellow Dog and click Import Counts From…

- Select Add counts from Session.

- Click Launch Sync YDI with Handheld. This will sync the device with Yellow Dog Inventory and allow you to choose the sessions you wish to import.

- Select the sessions you would like to import and click OK.

NOTE: If any problem items exist in the import, Yellow Dog will show you now. Examples of problem items include inactive/removed items that were scanned or items that are not assigned to the store.

If the item is in the system, selecting it and clicking “Edit Item” will prompt you to fix it, either by un-deleting it or making it active in the store.

Alternatively, you can remove it from the session by clicking “Remove Selected” or “Remove Problem Items” to remove all problem items in the session.

Single Scanner

To add multiple sessions from a single scanner after running the sync, select every applicable session that you would like to import.

Multiple Scanners

To add multiple sessions from multiple scanners, repeat the process for a single scanner as many times as needed.

NOTE: After the first scanner is synced, that scanner’s sessions will appear again in each subsequent scanner’s synced sessions. You do not need to import these again. Ignore them and import the unique sessions from any subsequent scanners.

Multiple Sessions for the same Physical Inventory

In Yellow Dog, you can have multiple sessions for one physical; whether manually keyed in sessions, synced from data collectors, uploaded from the Apps or a combination of the above. When importing these sessions into a physical, each session will create a new column with the session description at the top. This is useful when dealing with large amounts of inventory, for control and count purposes.

Worksheets

Replenishment Worksheet

The Replenishment worksheet is a tool that utilizes a designated warehouse store to generate requests or transfers for multiple locations within a single screen. This tool uses algorithms to decide which store’s requests get priority fulfillment based on sales for a chosen timeframe. **Pars and Reorder Points must be set for this tool to work. **

To start a new Replenishment Worksheet, navigate to the Replenishment tab on the left-hand menu.

Select “Add” from the right-hand menu to open the Replenishment wizard where you can choose to create a new document or use a template from a previous document.

On the next page, add filters to the replenishment. If you choose a template, the filters will be pre-populated but can be modified as needed.

- The description will be the identifier on any other purchasing docs that are created from this document. Add an extended description to the field below that if needed for more granularity

- Choose the store fulfilling the replenishment (usually a warehouse but you could use this for store to store transfers as well).

- Identify the stores that will be receiving items (also known as the replenishment stores).

- Select specific Levels or Vendors to help keep lists shorter and easier to work with.

- Choose how you want your data sorted in the worksheet by selecting from one or more sort option dropdowns. If no sort options are selected, items will follow your global sort selection (usually alphabetically by description).

- The sales range you specify will be used in the worksheet’s “Smart Maths” function to calculate the usage and determine which store should get what quantity of an item based on the sales percentage when the warehouse store does not have enough stock to fulfill all quantities needed.

If you plan on using this filter arrangement again you will want to choose the “Save as Template” option on the bottom right of the screen

Once you have set all your filters you click the “OK” button at the bottom right of the wizard to open your worksheet.

From the worksheet grid you can review and edit the reorder points and par levels. You can also set multipliers by item or across the whole grid if you do not want to permanently change your standard pars, but know that they will be insufficient for the current replenishment need.

Once you have reviewed your worksheet quantities and made any necessary changes, use the Commit Replenishment button at the bottom of the screen to finalize the worksheet. Once committed, Yellow Dog will generate and commit the documents as specified in your Options / Global setting.

For the example below, the Options / Global setting for replenishment was set to generate Transfers and leave them uncommitted. Note that the documents’ Description field is populated with the Replenishment code and description.

Contact your Implementation Guide or Support for assistance in configuring your settings for Replenishment including document type, commit option, and Smart Maths algorithm.

Purchase Order Worksheet

The Purchase Order worksheet assists in generating POs for multiple stores within a single screen.

From the Purchase Order Worksheet list, use the Add button, then select the parameters to create the Purchase Order: Vendor, Buyer and Receiving stores. Click OK to open the Purchase Order Worksheet editor.